- Home >

- Security and Safety Insights >

- The Difference Between Lockout Tagout Safety and Electrical Safety

The Difference Between Lockout Tagout Safety and Electrical Safety

There's no question that electrical safety is a complicated topic. With so many different types of activities and hazards, it can be very catastrophic if not managed appropriately. That’s why it’s so important to have a clear understanding of all the nuances to ensure the safety of your employees. Understanding the overlap and differences between electrical safety and lockout tagout safety is a prime example.

Why the distinction between lockout tagout safety and electrical safety has wide-reaching effects

Oftentimes, the terms “lock out” and “electrical safety” get confused – and that can impact everything from policies and procedures to knowing who is responsible for doing the work.

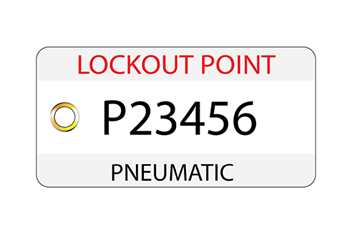

Lockout refers to the mechanical isolation of hazardous energy on a piece of equipment ensuring it gets to a zero energy state. Any equipment with two or more hazardous energies present requires specific, written lockout procedures based on the OSHA standard 1910.147 and Canada's CSA-Z460.

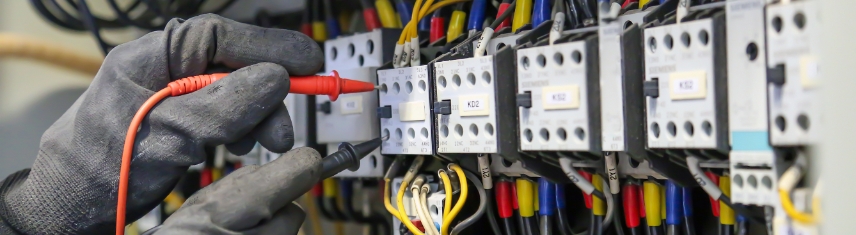

Electrical Safety

When you’re dealing with electrical safety, such as work on an electrical panel, you are not required to have a lockout procedure due to electricity being a single source of hazardous energy. However, you will need to have an electrical safety protocol guiding your overall electrical activities with any specific electrical task. These guidelines are governed by the NFPA 70E as well as OSHA 29 CFR 1910 Subpart S and CSA-Z462 requirements (if your business operates in Canada).

Understanding roles and responsibilities

There can also be confusion over who is qualified to conduct service and maintenance activities within an electrical device or panel. At times, organizations have a very small group of designated maintenance employees responsible for everything within a facility – from servicing a piece of equipment from a mechanical standpoint to conducting electrical work within a panel. If that person is not specifically trained to do electrical work, there’s a significant increase in the potential for incidents or fatalities as a result of things like arc flash or electrical shock. The importance of having the right person for the job or task is crucial.

Authorized Individual

For lockout, we are generally talking about “authorized individuals.” These are employees who have been given approval by the organization and trained based on 1910.147 to shut down a piece of equipment according to that specific equipment’s lockout procedure. Not only should authorized individuals be trained on their role and responsibility to 1910.147, but specific practical training for the unique policies and procedures that are particular to an organization's environment, equipment, and process for each piece of equipment they will encounter.

Qualified Individual

For any kind of electrical work, only a “qualified individual” is allowed to perform those tasks. A qualified individual is someone who has been trained to the NFPA 70E standard in relation to each specific piece of equipment and has been deemed by the organization to be qualified to conduct electrical tasks.

Supporting your safety program

Proper training is what helps keep your employees safe so it’s important to understand when specialized training is required. Whether it’s for lockout or electrical safety, you need to be aware of what equipment is being worked on, what type of task is being done, who is doing it, and what type of hazards are present. Once you assess these essential pieces of information, then you can accurately determine the type of training necessary. Training should be customized to each organization and specific to the type of equipment based on the tasks and responsibilities being asked of your employees.

If you are a company with limited internal resources, it’s important to note that there are third-party options available to help you safely perform many of these tasks. Master Lock has the experience to help you keep your people safe and your business compliant – from evaluating your program and writing policies and procedures to helping you maintain your program moving forward.

If you are interested in learning more about Master Lock Professional Safety Services visit our website.